Everything posted by savage bulldogs

-

a few pics of my project so far

Sorry no pics im afraid fellas lol I didn't think she should have had it done and she certainly didn't need it imo , at least she won't be spending any scooby modding money on shoes ..... As i Don't think she can see her feet anymore Mind you if Id have had it my way the money would have bought a twin scroll conversion bigger brakes and a 2 door re shell :-)

-

a few pics of my project so far

Cheers mick tbo most of the write up was copied and pasted off my local forum Gambit the mrs did say I could have the forged build and the 6 speed if she could have new norks . Who am I to argue :-D Will admit i Might by her some low cut tops for xmas and bin the elbaich suspension for rock hard coil overs to get the most outta her mods though ;-) I edited the 6 speed conversion in on this post as we lost a few pages when the forum had some server issues You can use the 5 speed clutch,clutch slave, flywheel and starter although I chose to use 6 speed items that came with the box (due to the larger dia clutch plate handing more power). The 6speed was out of a 04 plate uk sti with ppp and had female drive shaft sockets so I bought this stub axle conversion kit from importcarparts And one of it fitted (so it matches up with the classic drive shafts) with new drive/ prop shaft seals As i couldn't afford the rear 180 hubs and brakes I was lucky enough that the 97 uk turbo has a 3.54 ratio rear diff it matches the ratio of the UK sti box . Therefore I could retain my 160 rear diff, shafts and brakes until funds allow for the upgrade to the 180 set up . Other than the stub axle kit and everything else needed was in the kit I bought . 6 speed uk gearbox 6 speed Gear shift 6 speed Cradle 6 speed Prop shaft I had to use the bit of classic loom (with black and white plugs on) off the 5 speed so it matched up with the 97 loom but otherwise quite a straightforward conversion . Although it was !Removed! heavy to fit and the weather's been ****e im well chuffed with the difference 6 speed has made And glad the 5 speed spat it's dummy out now ;)

-

UK v5 Wagon

Nice work matt and good luck with the mot Did you have to shorten the brake fluid reservoir to make the newage tmic fit ?

-

a few pics of my project so far

Yeah I like the idea of less lag too :-D as a big single scrolling turbo would take a bit longer to spool ,but would pack a bigger punch when it did come on full boost .which is why most like the pull of a turbocharged car compared to the smoother pull of a bigger n/a engine (which id imagine the twin scroll would be like). I've got plenty of time to make my mind up anyways as either option would cost over £1k and after the engine build , 6 speed and the mrs boob job this year im pretty skint lol

-

a few pics of my project so far

Imo the tmic isn't a very good design as it suffers from heat soak when stationery (scoop doesn't blow air through it ) I've also heard of newage tmics running close to 400 but, a fmic and induction kit will be next on the list for me . Still haven't quite made my mind up on the "bigger " turbo as I'm toying with the idea of a twin scroll set up ;-)For drive ability on the road but ,I'd have to change sump (and oil pick up/dipstick) headers, upipe, downpipe and turbo if I did .which would give less lag than a bigger billet turbo but more cost and hassle

-

a few pics of my project so far

due to the 2ltr crank 500 hp is the max hp the engine should be good for. After the running period I fitted a fpr and 555 nismo injectors (which will be good for just over 400hp) and had it remapped by jgm. while having it remapped it seems more than fast enough for road use at about 330/340 :) so I was in no hurry to do anything else for a while but shortly after the remap my 5 speed turned into a 4 speed and died so its now running a 6 speed with exedy pink box clutch .so It now would seem a shame not to find a bigger turbo to break the 400 hp mark the 6 speed clutch is good for only really encountered 2 major problems so far :( firstly I pushed the crank seal in to far which caused a major oil leak at the back end which meant I had to remove the engine ,replace and refit the crank oil seal then refit the engine doh lol secondly the car pulled sweetly during the mapping session and simon said it was running about 330 hp /340 flbs and felt quick ,but a rolling road day showed only 290/ 270 after looking at the afr ,power and boost graphs both me and simon think their so similar to the previous map that im not running his new map due to my fandangled alarm system cutting the power to the esl'd ecu during the transfer of the maps so hes gonna have a squint at my scoob this weekend to try to suss whats up B)

-

a few pics of my project so far

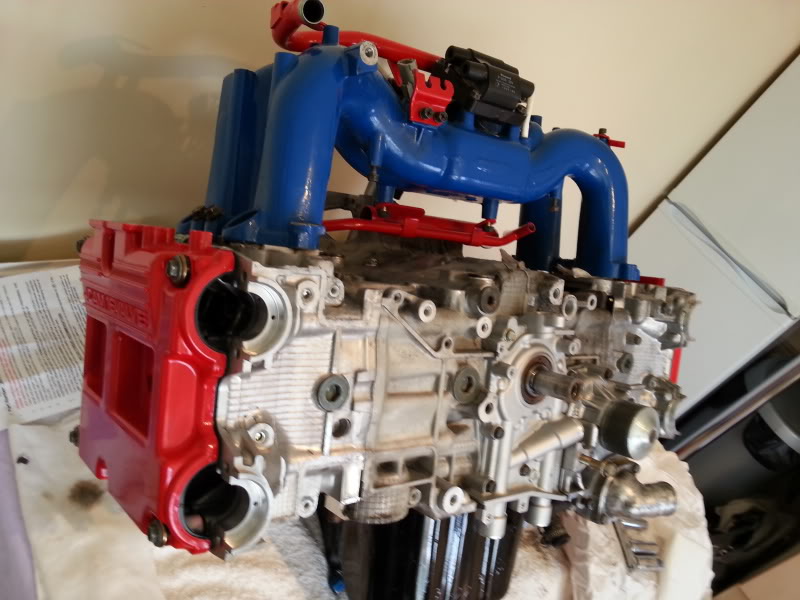

I was inspired by a few threads on other forums and gave up the pub to put my money and time to better use ;) the build cost me just under £2k and probably 3 weeks of my time (evenings and weekends) I used a spare inlet to remove the old engine and set about stripping the water crossover pipe and sensors and fitting them to the new engine with the td05 . then cleaned the engine bay up a bit and lowered the new engine in using the old inlet next up fitting the shiny inlet with everything attached once the auxiliaries and tmic were on filled it with fluids and turned it over by hand a few times unplugged the crank sensor (so it wouldn't start straight away) turned it over a few times with the starter motor to get the oil all round the internals before the initial start up😉 plugged the crank sensor back on took a deep breath and turned the key ...... started on the button sounding sweet with good oil pressure and heres a couple of pics of it fitted

-

a few pics of my project so far

Make sure you at least un plug the alternator (preferably remove it all together) as if you poke it with a with a wire brush connected it tends to spark /crackle and scare the crap outta you lol . I was fairly lucky with the weather around spring time (As most of you know the engines fitted now with 2k on the clock) .just thought I'd share what I've been up to (with a few pics ) and in case it helps anyone else with their project . Thanks again for the comments chaps . Clive

-

a few pics of my project so far

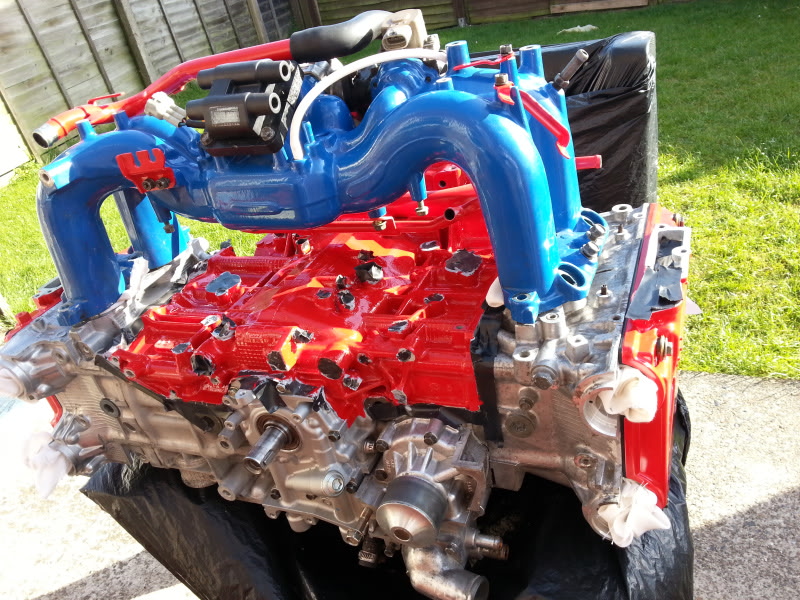

Im sure the pink dipstick is up to someone's taste jay , but not my cuppa tea lol got the converted tdo5 back from the engineers and will be fitting new seals on reasembly ,i know i wont be able to push the limits of my build with the tdo5 but it stands me in £40 for the welding and seals and should let me reach near the 340hp mark after its run in:cool: made a start on a friday evening stripping auxiliaries and inlet off my scoob so i could start cleaning prepping and painting them and there was'nt a great deal left under the bonnet by the time id finished 😢 once the rad, alternator and power steering pump are off the engine loom unplugs from either end and you can remove the inlet manifold with inlet pipe,fuel lines,injectors,throttle body ect in one piece once id made note of where all the pipes and wires went i stripped cleaned everything .prepped and painted the fuel lines/rails and header tank and left them to dry over night . as the weathers been rubish today all iv managed to do is fit the water crossover pipe/and the senders and sensors to the new block .Then re assemble the inlet parts but, i will admit it took a lot of time working out the correct route for the fuel lines ,vacume pipes and wires anyways as i did'nt have a section in my pdf manual for the v3 inlet so just worked of memory and a few pics i took ,did make life a bit easier having the other powder coated inlet ready assembled .

-

a few pics of my project so far

Next up was porting the headers and turbo exhaust housing, a bit of cleaning and getting the engine ready to be fitted porting the headers heres a before and after pic dialed in the cams and fitted the kevlar timing belt , I went with the gates belt rather than the cossie as id been told that their both made in the same factory but ,the cossie one costs £80 more .also I used the earlier hydraulic tensioner ,rather that the v3 and above spring loaded tensioner, as their stronger and less likely to fail fitted the ported headers and haywood and scott upipe then ran out of things to do untill i start to strip my scoob Think so i started cleaning parts under the bonnet started with the alternator as it looked a bit manky after a bit of time with a wire brush followed by cleaning a few other parts and painting the aux belt cover

-

a few pics of my project so far

did'nt take to many pics of this stage of the build but, made a fair bit of progress instead ;) cleaned the cams and cam caps , plastigauged the clearances on the bearing caps (which were fine) coated them in fresh oil/lubed the bearings with graphogen paste and fitted them with the cam lobes at base circle (lobes not pushing on the valves) .Set the cams in postion acording to the manual fitted the rear cambelt covers ,cam pulleys,all the new rollers and new hydrolic tensioner all that was left to do at this stage was fit the kevlar timing belt ,untill i Could free up a long weekend to fit the engine,because i dont have the suitable auxilairies,pipes,fuel lines water pipes ect ... due to the v1 long engine componets not being compatable with my v3 scoob .So i'll have to strip and clean them off my car and fit them to the forged long engine before i fit it into my scooby ;) chucked the inlet on top and poked the 550's and caps on top to see the finished look (again lol) excuse the !Removed! pink dipstick it was on the long engine when i got it ...:o honest as for the dog its always under my feet

-

Battlefield 4

+1 for cod being at it's best when it was ww2 as it's now full of quick scoping muppets with no tactics . Stanton try setting your controller buttons to "veteran " in the game options bud , not exactly the same as bf3 but close enough to help ;-) Gambit I haven't played single player on bf4 yet but the online game has crashed a few times and will probably get tweeked soon by ea . I have played a wrc series game before (wrc 2 i think) so i might stick wrc4 on my xmas list then (with gta)

-

Battlefield 4

Switch it on before you start as there's a few gb to download before you get stuck in ;-)

-

whats the stock turbo for 1997 subaru impreza wrx

I'm fairly sure the version 1 &2 wrx's and sti's ran a tdo5 16 g (power difference was created by the map and intercooler flowing better ) im unsure what the early uk's run but my v3 uk came with a tdo4 as standard. vf series turbos came in on version 3 and above sti's. Where as the v3 and above uk turbo's and (i think also) wrx's ran tdo4's . I do know the main differences between the vf's and tdo series though. Tdo series are a journal based turbo's ( basically shaft through the middle which is lubed with oil by centralfrugal force ) they can take more abuse and can be easily rebuilt . Where as the vf series have roller bearings which spool slightly quicker but don't tend to handle to much abuse and can't be rebuilt (as easily)

-

Battlefield 4

Just spotted this thread ,as I've been busy on xbox playing bf4 , which looks loads better than the beta version but nowhere near as crisp as those p.c shots . haven't quite made my mind up which next gen console I'll be going for yet but , I'll probably get one at easter once the price has come down a bit and there's a few more reviews to be read . As for driving games mcrae , forza and test drive unlimited on the xbox have been a few of my fav's

-

cheap mods

Result glad it worked out for you Bit cheeky charging extra dough for a universal part just because it's for a different motor though ;-)

-

a few pics of my project so far

Cheers chap stripped and resprayed the small (black) block water pipes (that come from the water pump behind the cambelt cover),wire brushed and cleaned the bungs/oil pressure sender bevel ,timing belt tensioner bracket,and oil cooler and then fitted them all . doesn't look a great deal different to last time ( apart from having a coat of red paint ) but heres a pic anyways 😉

-

a few pics of my project so far

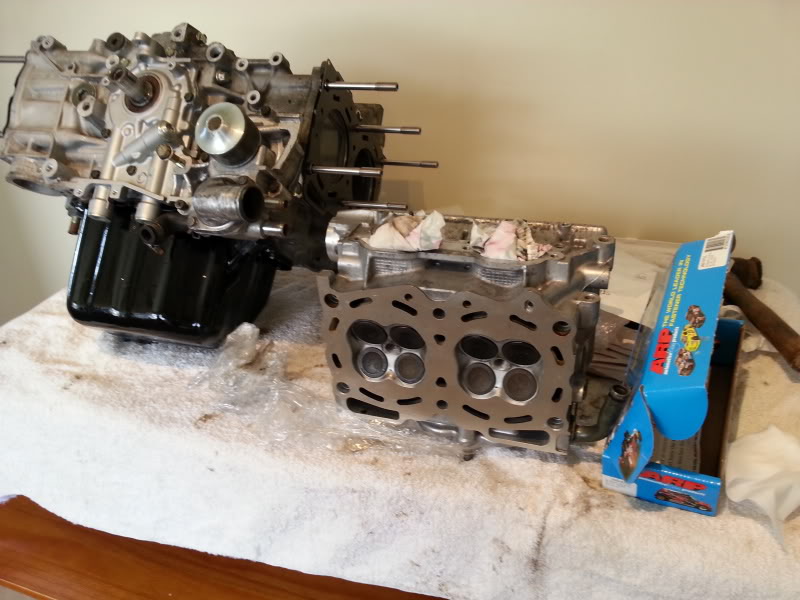

Thanks again fellas started off cleaning the threads out for the ARP head studs and according to the instructions your supposed to just fit them hand tight but, while doing my research (prior to the build) there's a few horror stories about them working loose .so I used loctite on the block end threads and used the small end of a allen key to slightly tighten them into the block . I applied the thread torque grease (that ARP supply with the studs to aid correct torque settings) and the cossie gaskets degreased the surfaces of the heads and block coated the ARP studs ,nuts and washers in the fastener lube and torqued the heads down in correct stages and sequance once heads were on i'd been advsied to leave the cams out so i could re torque the head bolts tomorow (let them settle over night) so i put the cam covers on to keep things clean and plugged all bungs ,inlets and masked threaded holes to get on with wire brushing the block and painting the acid etch primer on At this stage i could'nt resist sitting the inlet on top just to get a idea of the finished product😊

-

a few pics of my project so far

The mrs was fine with me using the kitchen table as long as I put towels then cardboard another layer of towels with a sheet over the top (and of cause flash wiped everything afterwards lol ) And yes gambit those pins are a pig ,you have to remove all 4 to split the block . I used a bbq kebab skewer to remove em lol as you have to take the outter circlip off and tap the wrist pin out from the other side (through the opposite access hole ) Next up i fitted the splash guards ,oil pick up ,group n gasket and sump on .followed by the rcm oil pump, water pump and cool running thermostat .

-

a few pics of my project so far

Cheers for the coments chaps and sorry for the late reply but ,what with the rolling road day , my map problems and the mrs being in hospital it's been manic . I started off by degreasing and blowing everything through with a air line id decided to delete the oil squirters to get over the problem with the contact they made with the piston skirts .Pat ( my engineer) had give me some suitable grub screws and i covered them in loctite (so they dont vibrate loose) the main reason i started the build in the first place was because of the piston slap my engine has when its cold and as id decided to aim for a maxium of 550 hp the piston to bore clearance was at the lower end of mahles spec .which should make it a bit quiter when cold but meant i had to adjust the ring gaps on all 8 compression rings to avoid the heat expansion causing a piston to swell and trap in the bore . I checked the gaps with a feeler gauge for each individual bore/piston yet again kudos to pat (engineer) as no matter where in the bore i positioned the rings they all had the same .009" gap you adjust them by gradually filing (both ends at once) by closing the ring around a file or stone to bring them to the required gap size i oiled and fitted the rings to all the pistons making sure each ring gap was in the right position acording to the mahle spec sheet .As you dont want the gaps inline cos you'd get "blow by" .before i slid any pistons into a bore i coated the bore walls with graphogen paste to help with initial start up . As subaru engines require you to fit the wrist pins (to connect the rods to the pistons) via a fidiley access hole i decided to connect the the right bank rods and pistons ,fit the circlips and drop them in the bores i could now connect all the rods (and the ones with the pistons attached) to the crank which makes life a bit easier, as i only have to use the access holes for fitting 2 pistons now 😉 once id torqued the arp big end bolts on the b.c rods i prepped the other block halve by fitting the new seals to the water and oilways ,smearing graphogen paste on the acl'd mains and give the block halves faces a coat of threebond liquid gasket i copperslipped the dowels and lowered the block half (with the pistons and crank in) onto the half with the "o" rings in to keep everything in place ,then torqued up the new block bolts(with new dowty washers on the ones in the waterways) in sequance i fitted the inner wrist pin circlips and managed to fit the other 2 piston and wrist pins/circlips through the acess holes but was chuffed i only had to do 2 as they are propper fidiley

-

rr day October 26th in norwich

He broke it about a month after he finished it :-( had a babe on the way (hence the s4) As for the camper van the bloke was running a 450 hp scoob engine anyway but, said he wanted the front wheels to lift higher off the ground when he hit the throttle :-D

-

rr day October 26th in norwich

Yeah you might have heard of my mate worbs (with the s4) as he had a few build threads on scooby fourums of his "black bird" 550 hp stroker classic .I helped him brake his scooby (as he couldn't sell it whole) the engine ended up in a flat bed splitty camper van :-D I did fid this pic of the mk2 golf he converted it to awd , forged the 18t engine, and strapped a massive turbo to it . I'd have loved to have seen it on the rollers

-

rr day October 26th in norwich

Think the type r has dccd but im unsure if his is wired up due to running a 6speed . It's supposed to be running 2 bar of boost (dyno'd@ 1.8 bar) and the gt40 hits full boost at about 5k and just lights the tyre's lol . He couldn't shake me from his rear view mirror though due to mine hitting full boost by 3.5 k but my fueling is all over the place at the moment :-( . It was a good laugh all the same and only 2 no shows . My mate with the s4 sold it and bought a 330 d:-( And the 1800T 4x4 mk2 golf hasn't been finished yet ,but its a mental machine which should be running 600+

-

rr day October 26th in norwich

There was a st focus as well but, the s4 or the 1800 t mk2 golf didn't make it unfortunately . I followed steve up there and when his gt40 came on boost the !Removed! end squirmed whatever gear he was in , I think it's gonna be a animal once it's sorted :-D

-

rr day October 26th in norwich

Didn't quite get the figures I was after on the rr session 290 hp in a 6 speed classic ain't slow but I think it was running the old map due to the afr graphs (long story lol) Didn't take to many pics (and they were on my phone) The black v8 mustang was on the end of the row And a couple of Steve's stroker type r which made just over 420 hp (due to a possible boost leak)but , shoulda made 500+