-

Posts

5,456 -

Joined

-

Last visited

-

Days Won

392

Content Type

Profiles

Forums

Events

Gallery

Store

Premium Membership Discounts

Subaru Videos

Subaru News

Everything posted by savage bulldogs

-

Help needed please !!! V4 impreza project

savage bulldogs replied to Pizzle's topic in Subaru Impreza Club

Do you have dash lights with ignition on ? Does it have a aftermarket alarm ? Can you hear the fuel pump prime ? Do you know what version bottom end is in it now ? -

a few pics of my project so far

savage bulldogs replied to savage bulldogs's topic in Subaru Build Threads

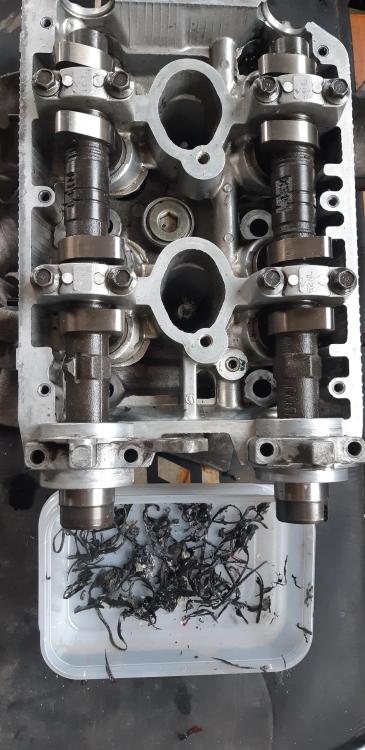

Finally I've got a dry space to work on my car 😎 Unfortunately the next major project isn't for my 94 wrx sti .... it's for a mates 94 wrx sti 🙃 Will be building something Very similar spec to mine... Closed deck block ,2.5 crank , 14mm headstuds and v3 sti heads . So first up is removing the heads from a knocky v3 sti engine. Now I've just got to make it look like mine heads off never seen soo much sealer used on cam covers , probably the cause of the bottom end failure. As this is what came off the left hand cam cover , cams ,cam caps ,spark plug holes and cam cover 🙄 at least they're definitely v3/v4 sti heads, as they have the separate shims under bucket 😎 At least the cdb , forged internals and gasket boxes passed the "sully security sniff " at the door 😂 be a while before I start building the block, as I want the heads back from my engineer, so I can bolt them to the block to seal it up till fitting. -

I don't know for sure but if you can hear the pump I'd imagine it's more likely to be something other than a fob to car "communication " issue /reset . As most alarms cut the power to ECU/pump /starter motor. Hopefully it's just a communication issue , by one fob battery dying. Give subaru sigma alarm pin code override a google , hopefully a guide will come up and sort it 🤞

-

Cable to hydraulic clutch swap on 2000 non turbo impreza

savage bulldogs replied to Lily's topic in Subaru Impreza Club

Unfortunately, I have no idea if the crank bolt pcd and fitment are the same on 2ltr na and turbo . I do have a v4 sti engine and flywheel in the workshop atm though . If the clutch you bought was for a "classic turbo" it will definitely fit any classic flywheel. If you measure the centres between the flywheel bolts ,diameter and thickness of the flywheel, I could compare them too the one I have . At least if it's the same measurements you give , it would be more likely to be the same dimensions elsewhere. So might be worth buying a turbo version flywheel and then see if you need the starter motor too . -

If you have a spare key , do you have a metal tag with a code on it in with the paperwork? If so and on bug /blob (maybe hawk) this can be entered into the sigma keypad in a compartment by the drivers right knee . As it does sound like a alarm fault, having neither the doors unlock and not starting. Can you hear the fuel pump prime when you turn the ignition on ?

-

a few pics of my project so far

savage bulldogs replied to savage bulldogs's topic in Subaru Build Threads

Had Danny from practical classics magazine pop over during the summer . Although he took a few pics and asked a lot of questions, I didn't really think my 94 jdm was their sorta thing . So was well chuffed to spot it in this months magazine release 😎 Of course I gave my engineer (Seager engineering) ,the main parts supplier (Alyn @asperformance) and the Subaru owners club forum a mention too 😘 -

I run dba t2 discs and performance friction carbon metallic pads on my 94 sti's brembos . Found them a great combo for fast road use , sometimes get a tiny squeal 1st time I use them but good bite from cold and no fade when reining in 400hp . I got mine in the uk from Alyn at Asperformance . His website isn't the best and it doesn't list all his stock . So best to give him a call , as unlike most other aftermarket suppliers, he'll take the time to sell you what you need. Rather than just sell you the most expensive overkill option for your budget/usage

-

a few pics of my project so far

savage bulldogs replied to savage bulldogs's topic in Subaru Build Threads

Yeah , unfortunately I've had to render over much worse in the past 20 years but at least I know i can make my attempt at blockwork look purdy 😂 It is a bit cold in there ,being single skin , might consider a pass of (waterproof agent loaded) sand n cement render . Then insulation board and a colour silicone render finish . Either that or nylon mesh reinforced sand n cement outside and insulate the inside at a later date instead 🤔 Tbh the second option will suit my budget/needs better, as I can get the exterior rendering finished and painted for under £200 . Then worry about the insulation values at a later date , if needs be . But for now it's just nice to see it out of the rain and sat indoors 😎 Mind you I might regret not managing to get it insulated this year , when building my mates 2.1 over the winter 🙂 -

Legacy 06 2.0 twinscroll (WHAT MODS TO GO FASTER?)

savage bulldogs replied to Leggyjake's topic in Subaru Legacy Club

As above for early warnings if pressure drops or it gets too hot . The impreza classic, bug and blob all have fuel cut issues when low on fuel (1/4 tank and below ) whilst cornering hard right . Due to the shape of the underside of the tank (hump to clear prop /diff) and the fuel pump pick up being on the right . Not sure if this applies to the legacy though ? If so a spec c type fuel sock cage (in tank) or a external fuel swirl pot will help . If you intend on really going for it on track, a baffled sump helps lessen the chance of the oil sloshing around in the sump and starving the oil pick up (losing oil pressure when cornering) . As for faster , less weight , a decent geometry set up ,decent tyres and a remap . -

a few pics of my project so far

savage bulldogs replied to savage bulldogs's topic in Subaru Build Threads

Yeah got to lay about 120ft of armoured cable and then run a ring main /lights . Thankfully I'm a plasterer, so covering my shoddy blockwork with a few coats of render is on the list too . Got another 2.1 cdb with v4sti heads to build in there over winter for a friend too . So a fair way off buying a tig welder and finding the time to finally make some better reversed inlet pipework 🙃 But at least I'll have something more scooby related to post on here -

When was the last time the spark plugs/ air filter were changed and was the replacement o2 sensor a genuine Subaru part ? Try checking for vacuum lines or intake air tract leaks , if you're not sure how to do this yourself. Ask a garage to do a "smoke test " As a misfire or air leak, could send unburnt fuel through the exhaust and give a o2 sensor fault .

-

a few pics of my project so far

savage bulldogs replied to savage bulldogs's topic in Subaru Build Threads

Had the mot and she passed with no advisorys 😎 mind you I only managed 350 miles in it this year 😥 At least I used my spare time for something scooby ,by building the workshop. Blockwork finished . windows glazed steel doors fitted roof trusses made , roof sheeted and felted Still got to lay the armoured cable for power and cover up my shoddy blockwork with some nice flat render but ... she's indoors and I finally have a dry space to "play" -

2006 sti will not start

savage bulldogs replied to Craig123's topic in Subaru Engines, Exhausts and modifications

Does the other bank spark all the time or stop after a full rotation? As I had a similar problem when I had a bent pin on the crank sprocket. It would turn over ,spark once and then cut spark once it noticed the bent sprocket pin Did you change any of the cam /crank ,pulleys/sprockets ? (UK, jdm pulleys can differ even on the same year ) Although you have compression due you have enough on all cylinders? Double check the timing belt Mark's. If you have avcs and Tgv's are these plugged in correctly and functioning properly? -

a few pics of my project so far

savage bulldogs replied to savage bulldogs's topic in Subaru Build Threads

Been to a couple of local meets but haven't had the time for doing scooby 😥 So 4 months later and I'm still waiting for summer to start but on the occasion that it hasn't rained at the weekend.... I've been busy. Not so much scooby stuff but I'm almost ready for a roof on the workshop 😎 As for the little puppy .... well he's not so little at 8 months old -

Hi n welcome, nice looking car and history . I've owned my 94 sti for almost a decade and it was my brothers before he sold it to me . Think that's the first blobeye I've ever seen with morettes fitted , its normally bug eye that get the lights switched . Spoiler could possibly be a s203 item but hopefully someone else can clarify that for you .

-

Gearbox Code - where can I find info except on the box?

savage bulldogs replied to CondorOB1's topic in Subaru Legacy Club

On manual 5 and 6 speeds the code is on a white sticker on the bellhousing near the starter motor (ty####) . Otherwise if its definitely the original box it might be on a silver id plaque on the front suspension turret . -

Are you running the stock ECU? If so you might be able to use the ECU self code check function. If not I'd start by cleaning the idle control valve/maf and clean n re gap the plugs .

-

A normal size gallon/5ltr will leave around 0.5 ltrs to top up between changes. Personally I always run millers nanodrive and jdm black oe oil filter

-

a few pics of my project so far

savage bulldogs replied to savage bulldogs's topic in Subaru Build Threads

After over a decade I finally made a start on building a 30m2 workshop 😎 2 days and footings were dug out and skip loaded 😎 Then British spring weather kicked in 🙄 after the snow died off 1st course up to damp and sub base ballast in , ready to pour the base /floor I'll give it a break for a month, then start brickwork, hopefully it will be roofed in by the end of the summer 😋 -

Subaru Outback EE20Z oversized rod bearings +0,50

savage bulldogs replied to VPMParts's topic in Subaru Parts For Sale

Not sure where you are but generally most in the uk use import car parts for stock parts . Someone like Alyn at Asperformance (midlands uk) could probably source aftermarket (king , acl ect) oversized bearings if luke at icp doesn't stock them . -

We used to have a few uk legacy mods on here but haven't seen them post for around 2 years. Hopefully it's not another forum closed due to social media, seen a few close in recent years. Social media groups do serve a purpose but some page members give shocking advice and research/ searching functions are pretty useless for info /advice.

-

Hawkeye Wagon - Project - hello

savage bulldogs replied to London Wrx's topic in New Members Introductions

Hi n welcome, bought mine in my late 30's but that was over a decade ago. Front ends are slightly narrower on the wagons and rear bumpers /lights are different. Otherwise pretty much everything else is the same as on the saloons of the same year /version . So parts are fairly readily available for the wrx wagons. -

a few pics of my project so far

savage bulldogs replied to savage bulldogs's topic in Subaru Build Threads

He's getting bigger by the day and has gone from 4.4 kg to 10.2 kg in 6 weeks 🤔 fired the scooby up with him in the garden and he tried to run through the closed conservatory door 🙃 Bounced off without hurting himself, mostly thanks to being a Bulldog not the speed he was going 😂 finally starting to build the workshop next month so at least the scary scooby will be tucked up in a garage and outta the garden . Going to cut a pit into the floor of the workshop to make the soon needed clutch change and long waited winter rear end refresh eaiser too 😎 -

a few pics of my project so far

savage bulldogs replied to savage bulldogs's topic in Subaru Build Threads

House has been eating my time n money so much that the scooby has only done 400miles between mots 😥 With Christmas come n gone the only thing scooby under the tree was a spare set of unpainted areoguards but we did get a little something else new years eve ..... A new co pilot 😍 Meet sully the 9 week old (not so savage looking) bulldog , so happy to have another bulldog in the house 🙂 Even if he's taken a liking to my slippers 😋 Just not sure I'm ready to change my profile pic from being Lizzy (my old bulldog) yet though 🤔 -

Stock subaru (Mitsubishi made) tdo5 16g should be a straight swap . As long as they're both the same "entry" and fitted with the correct oil and water feed lines / banjo bolts for the turbo .... so I'm guessing it's a aftermarket turbo ? With some of the early md , blouch ect big Garrett based stock location turbos , they used to cut some of the bellhousing away . As the compressor housing used to foul on the tmic bracket mounting bolt hole (edge of the bellhousing) . These were big 450hp + turbos , so they were running fmic's and didn't need the tmic mounts anyway . Saying that if it's a big tdo5 20g it should still fit (mine fits fine ) . Tbh anything bigger than a 16 g on a any stock ej20 (other than the sti ej207 onwards ) is too big for the engine and 5 speed drivetrain hp limits . Just thought I'd mention , in case you wasn't aware .That any change in airflow/fuelling will need to be mapped in straight away, as fitting a bigger 350hp + turbo will flow much more air at a different rpm . So fuelling /timing and boost targets would need adjusting accordingly , to not damage the engine .