Everything posted by savage bulldogs

-

WANTED "ESL" BOARD

I know a little bit about esl's but bugger all about electronics they run with the factory ecu (rather than replace it) retaining the factory ecu's ability to advance and !Removed! the timing to reduce knock and read fault codes. although the early esl has been out for about 5 years the 97/98 version scoobs had a different "code" and the esl has only been out for those for just over a year or so .the 99/00 version esl board isn't out yet (but is in manufacture ) so I assume they run a different code as well and as far as im aware they don't do one for newage but, their catered for by ecutek licenced software (rather than esl's open source software) if you wanted to create a new interface for live mapping ecu's id suggest you drop the likes of simon @ jgm a email as hes a quality Scooby mapper who knows his software I do have to 1 pic of a early board fitted to a early ecu dunno if that's any use to you john

-

a few pics of my project so far

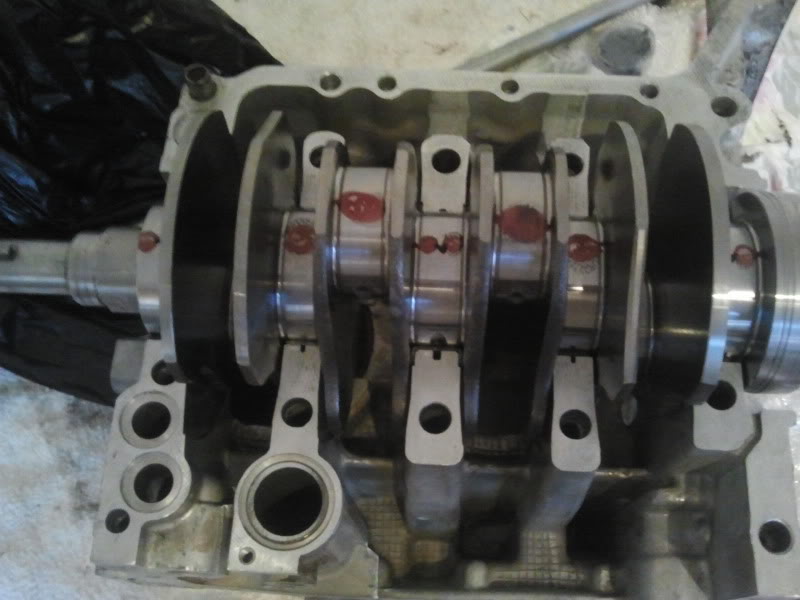

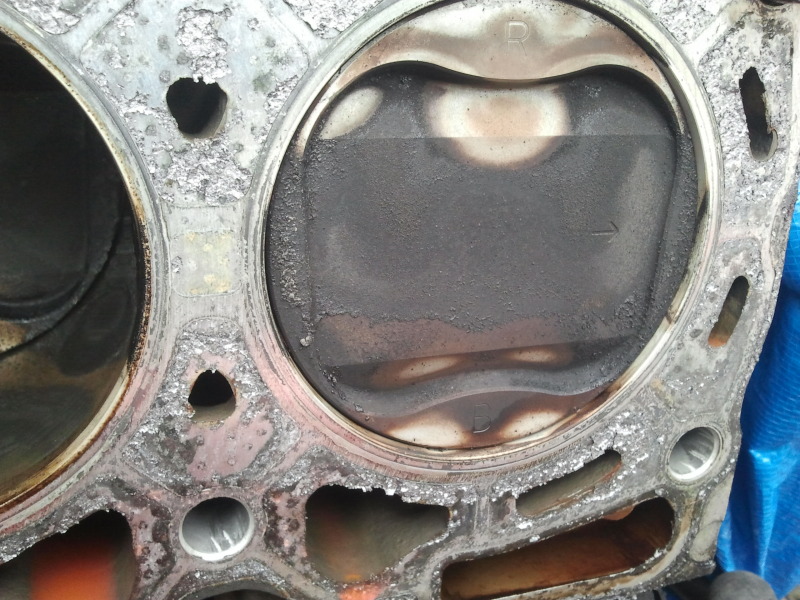

well the ocd mrs was kind enough to let me use the kitchen table to build the engine on :) and as her kitchen table probably the cleanest environment known to man, it was ideal to build a engine in :D the engineer said the crank was in perfect condition so I decided to get it ultrasonically cleaned as the 2ltr crank has sludge traps in the oil ways which cannot be rod'ed clean. which also saved me the cost of the 2.5 ltr crank and a thrust conversion ,that's needed to fit the later crank to increase the capacity to a 2.1"stroker" (due to a longer throw) Pics of the minty 94 crank and the quality of the deck face . started off the bottom end by fitting all the acl race series bearings to the B.C rods and then checking the big end clearance with plastigauge , basically (for those who dont know) its a thin strip of wax which you place on the (clean) journels of the crank before you put the big end caps on . Next put the caps on and torque to the correct settings then, when you remove the caps , the wax has compressed giving you the excact (oil) clearance between the crank and bearing (which is measured with a gauge) next i dry built the block (no liquid gasket between the 2 block halves) fitting the race acl's and plastigauged the main journals and torqued the block halves together in sequence both big end and main bearing clearances were well within the standard tolerances and nowhere near the "limit" tolerance subaru give for a rebuild id been warned to check for under bore oil squirter to piston skirt contact ,as the race spec mahles have a deeper skirt to cope with the extra power, so i assembled one of the pistons and rods slid it into a bore 😒 everythings been going well so far 😐 spose something had to cause a bit of a problem theres a tiny amount of clearance between the under bore oil squirters and the piston skirt, but not enough for my liking ,so i deleted the squirters by fitting a blanking grub screw. which is not a problem as newer piston materials dont need as much cooling and the mahles cool the gudgen pin via the oil ring .

-

a few pics of my project so far

Cheers jay and gambit I'll chuck some more pics up later of me building up the engine ,as it might help a few people if they are considering working on their own scoob , if nothing else it will help people be more familiar with the boxer lump ;-)

-

a few pics of my project so far

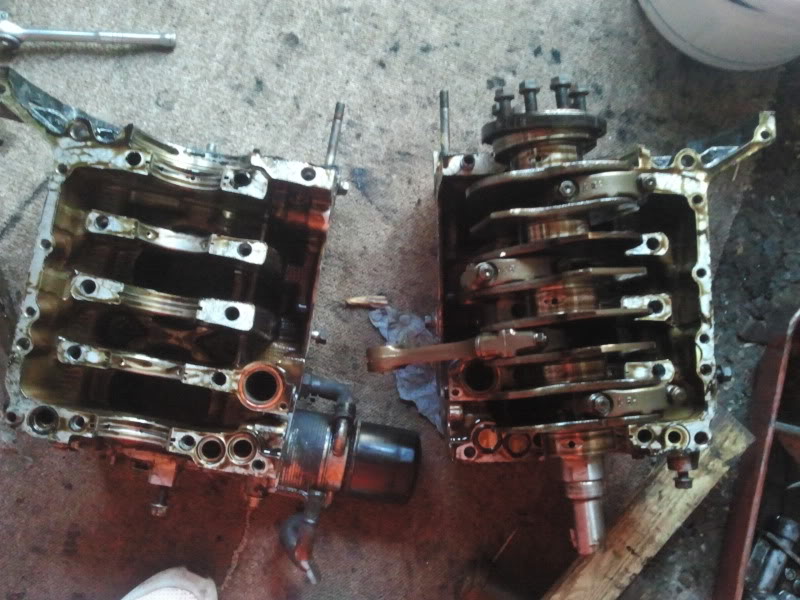

cheers gambit I will admit although ive rebuilt straight fours ,v6,s and v8,s in the past, its my first boxer build so I would have been a bit lost if it wasn't for the pdf service manual I've been using. IT'S A GAME WITH 2 HALVES ☺ next up was stripping the bottom end ,id removed the sump and all the case bolts but couldn't split the block halves they were stuck together at the modine end (bit with the ### marks in the bottom of pic bellow) so after about 2 hrs of putting bolts in the outer casings and trying to prize the halves apart 😠😤(as I didn't want to damage the block faces poking screwdrivers in) I did all the bolts back up and released the modine end first 😉 I sent the block halves and crank off to my engineer to check them over as id decided to fit a set of drop in pistons while it was apart 😊 by chance a friend had ordered the wrong rods for his build and sold me these brian crower sport compact rods for a price that couldn't be refused B) as their rated to 750 hp it seemed a shame not to buy pistons to match so I bought some race spec mahles which are also rated to 750 hp then got the rest of the shopping list together arp headstuds and big end bolts rcm oil pump acl bearings new block bolts full oe and group n gasket kit new timing belt rollers and tensioner Kevlar timing belt then got bored waiting for the engineer to complete the .5mm over bore (needed to fit the new pistons) and face skim work ,so I started to polish and paint a few bits .id originally decided to polish the cam covers and had already prepped them but after a bit more research had found that they would need to be re polished every few months or sealed with a clear lacquer so I painted the bare ally with a adhesion premotor, enamel primer and enamel paint picked up a powder coated inlet for £40 😎 Then painted a few pipes and polished the throttle body before assembling it all together

-

a few pics of my project so far

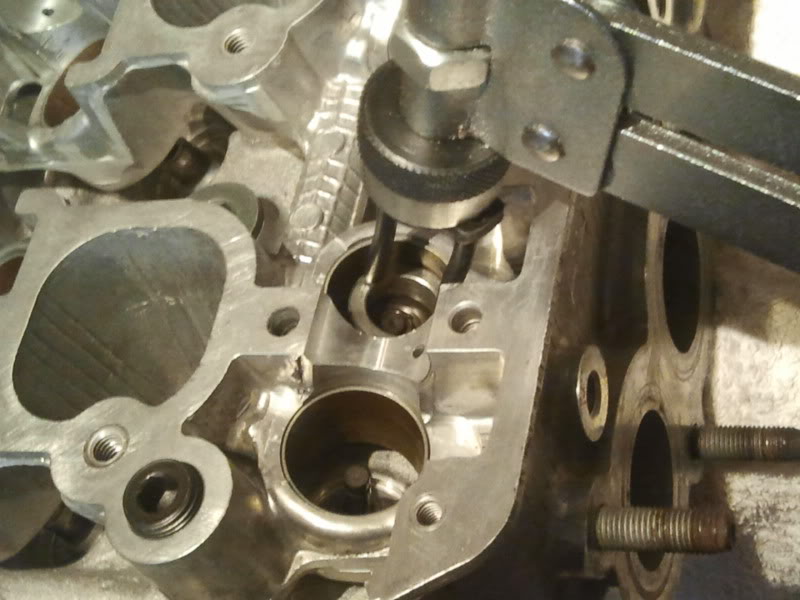

whilst saving for the machine work and gaskets I started to do a bit of work on the heads, light port and polish before stripping them down . standard inlets lightly ported and center separation "knife edged" and a light polish I started to lap the valves in but wasn't happy with the amount of contact area for the valves to seal ,heres a pic of before and after so I sent the valves off to the engineers (with the heads) and he skimmed the heads chucked the through his hot wash and re cut all the valves I then re assembled the heads with graphogen engine builders paste and new valve stem seals valves and collets in , proppa fiddly job 😐 lash caps in then bunged all outlets/inlets, sprayed the heads with oil ,wrapped them with cling film and put them in a box upstairs to await the bottom end build

-

a few pics of my project so far

well I thought id post a few pics of my never ending project which has snowballed from telling the wife "just a exhaust and remap then ill be happy" to a full engine rebuild , drivetrain swap and then a reshell I started off by looking for the cleanest and most standard uk classic my £2.5 k would buy me 2 yrs ago.I ended up with this my97 uk turbo 2000 which had full s/h 92k miles and was bog standard bar some braided brake lines B) Then kicked off with a k&n panel filter ,air box resonator delete,sports cat ,zigen cat back,sti tmic and strut brace while I was waiting for the 97/98 esl to be released (as I knew I could fit those without needing a remap) which changed the engine bay from looking like this to looking like this the 2 pot front brakes were so bad they were scary so they were replaced wiith a set of 4 pot front callipers (which I refurbed with stainless pistons and new seals) accompanied by groved and drilled discs and Kevlar pads then fitted a hta p1 rep splitter ,moved the number plate and fitted a crystal light pack to freshen the look and detango the lights closely followed by a esl remap with twin maffless maps which saw a increase in boost (0.8 bar to 1.2 bar) and power to 265 hp 😄 next I concentrated on a few handling tweeks that wouldn't make the kids chip their teeth in the back seat :) so I went for elbaich pro springs which are progressive rate and only stiffen up under load (when cornering) whiteline rear arb and droplinks and front ally droplinks which I think is a great combination for road use 😉 as me and my brv both own classics we bought a v1 sti with a few choice mods on in order to round up a few spares and I ended up with the closed deck block sti long engine left over which is where my project starts to snowball although the engine was making 340 hp with low knock on the apexi ecu controller I decided it would be rude not to strip and refresh the bearings gaskets and seals ;) once I started to strip it down I could see it had been well looked after due to the new water pump and timing belt and once the cam covers were off I was surprised how clean the engine was B) bearing in mind it was outta a 20 yr old sti 😉 similar story once the heads were off as the piston crowns showed just a build up of carbon that you'd expect and nothing untoward

-

Engine Oil Viscosity

Yeah I've been chatting to tim a lot as i always get my oils and fluids from opie ;-) I have got through quite a bit lately what with fitting fluids, running in oils ,filters and the fully synthetic millers im using now . I was only discussing with him today if I should change to a different oil grade for winter and while I'm running less than targeted power for my engine (as it's running colder than anticipated)

-

Engine Oil Viscosity

Wish I'd have read that before I phoned you today tim , Could have saved us both a bit of time :-) Cheers Clive

-

a little project thread of my turbo 2000

I think your right miggs as I'm sure ecutek is just the licensed software added to the standard later ecu. And I know esl do a early chip 92 /96 which didn't used to run mafless and a later chip 97/98 which does run mafless (which I've got in mine) Esl have either updated (or are in the process of updating) their software to include anti lag and launch control which I might have a look at soon

-

Engine Surge ???

.25 gap is fine fella Depending on which version of scoob ,The rear earth strap connects to the bell housing or ridge on gearbox (near the clutch slave) and the other end is connected bulkhead (near the "dog bone" gearbox stabilizer) or loom off the starter motor

-

a little project thread of my turbo 2000

Here's the esl board for a pre 97 classic I broke a while back

-

a little project thread of my turbo 2000

Esl is a chip (daughter board)thats soldered inside the ecu and runs with open source software to allow live mapping (I've got a pic somewhere I'll dig it out) I think the ecutek can be used on later classics (mainly newage) although I'm unsure if it is the same principle (board soldered in or just software added to the oe ecu) but you defo need a licence to use the ecutek software to map it

-

a little project thread of my turbo 2000

sounds like a plan B) I ran my self build in for 1k miles on the 380's (greys) with actuated boost (0.5 bar) and then fitted the fpr and 550's the day before the remap ;) as saved me the expense of getting a running in map done Admittedly I blew the 5 speed to bits 2 wks after the remap do you know if you've got a daughter board (esl or ecutek) in the ecu to allow it to be mapped ? as that could be a added cost you might have to consider if it hasn't already been mapped ;)

-

Engine Surge ???

have you got a boost gauge fitted ? as if its unmapped it should read 0.8 bar I run ngk 7's (not the ngk6's)but I think their the same fitment just a different heat rating . if you pop the plugs out (to do a compression test)check the gaps and look for cracks in the porcelain.as if over gapped the spark can be blown out by the boost and being awkward to fit ive heard of them cracking during install ,both of which give a misfire symptom . earth sometimes the earth cable under the tmic can either be forgot to be refitted or corrode .The loom plugs are 2 grey plugs that undo to allow you to remove the engine without unplugging every sensor . There located at either side one behind the windscreen washer bottle and one near the boost solenoid ,id check those and look for any break in the insulation on all the sensor plugs (cam,crank ,maff,map lambada ect...) ideally I guess you need to find someone local with the same version scoob that's willing to swap items over ie maff map ect as there the usual culprits for your symptoms. or find a local (or mobile)scooby mapper as they might be able to fault find a bit better than someone with a generic code reader.

-

Engine Surge ???

Has it done it since you've owned it ? Has it got any mods or been remapped? Maybe do a compression test (check the plug gaps / condition while there out) Check the map sensor , vacuum pipes and for loose loom plugs /earths Hope you suss it soon fella Keep us updated ;-)

-

cheap mods

Sorry for the late reply bud I forgot I posted on this thread . Yeah I've got the hard pipe from the servo (you can just see it beneath the strut brace) And I took the measurements from the two outter (drivers side to passengers side )12mm nuts on top of the strutt (theres 3 nuts on top of each strut That fix the strut into the suspension turret) . Hope you get it sorted fella ,let me know how you get on . Cheers Clive

-

a little project thread of my turbo 2000

Nice progress their fella As for the fuel pump I'm unaware of a front fuel pump on classics .I've fitted a walbro (in tank) pump nismo 550's and a fpr which should make the fueling side of things good for about 420 hp . if you're aiming higher than that you'll need bigger injectors , the bigger (walbro, bosh ....) pump (can't remember the model number) and possibly parallel fuel lines/ billet rails . although I'm unsure what hp the standard "in series" fuel rails go up to , I do know that they can make the last injector inline run lean when pushed. What injectors are you running bud ? As if their standard yellows (440's) they're good for 340 ish with a fpr but , don't just fit a fpr without having a remap booked in. as any slight difference in the fuel pressure will affect the fueling

-

opps

Yeah I'm sure it will jay. I can't moan to much about my self build making enough power to blow the 5 speed ,just glad she's back on the road .As I've missed the burble and boost in my life for to long this year lol

-

rr day October 26th in norwich

Thought I'd bump this as there's 2 spaces left and just over a week to go

-

Impreza STi PPP Version 10 hatchback

Hi and welcome What mods have you got already ? Id have thought front mount intercooler , induction kit and remap but ,I'm unsure what power the standard clutch is good for . Have you spoke to a mapper as they'd have the best idea as to what you'd need to reach your target or possibly more ;-)

-

opps

Just hope I can start to enjoy driving it now :-) as it was off the road whilst fitting the engine then I had to drive it like miss daisy with no boost for 1k miles (while running in) Then had it mapped then blew the gearbox up two weeks later .... And yes miggs 200 miles of smiles so far ;-)

-

Apexi boost controller (electronic)

Clicking might be the original boost solenoid (as it's still wired up) pop the bonnet and have a listen when you start it . I think The vacuum pipes from the actuator / turbo outlet should be connected to either a apexi boost solenoid or the controller itself . To bypass the controller I'm fairly sure that if you run a piece of pipe straight from the actuator to the turbo outlet, then it will run at 0.5 bar of boost (actuated boost) as I was advised to do that when running in my engine . If you do decide to go back to standard make sure that you put the reducer and restrictor pill back in the right place to stop the boost spiking .I think the details are on that thread but, if you can't find it let me know as I've got it book marked on my pc ;-)

-

Apexi boost controller (electronic)

If it's not been mapped I'd either put it back to standard or get a mapable ecu .cos as ash said the standard ecu will only compensate fueling for minor mods and with a fmic and boost controller your probably pushing your luck I'm afraid . What year / model is the wagon fella ? This thread helped me understand the vacuum pipe route on my scoob when I switched from 2 port to 3 port boost solenoid as it has some useful diagrams http://www.rs25.com/forums/f128/t157501-help-v4-sti-stock-boost-solenoid-setup.html

-

Apexi boost controller (electronic)

I'd trace the vacuum pipes back from actuator or outlet from the turbo as they should be attached to a boost solenoid , as it might have a apexi one installed in a different position and just unplugged the oe one

-

opps

the 6 speed's finally in and running .I'm well chuffed with the difference in quality of gear change and the 400 rpm less I'm doing at 70 in 6th is a added bonus . Now I just need to drink all the milk again so I can nip out in the scoob and get another pint :-D